How Mining Control Rooms Are Being Optimized in 2025

Mining control rooms are a critical hub of information for any operation in the mining industry. It’s the space from which mining control room operators make key decisions that allow this cornerstone of the global economy to operate efficiently and effectively. In 2024, the combined mining sector GDP from G20 nations alone reached $660 billion. The United States emerged as a major contributor, with U.S. mining operations generating $758.8 billion in revenue despite an 8.7% dip and employing 555,000 individuals.

It’s no surprise then that modern mining operations face tremendous pressure to improve safety standards while maintaining peak efficiency. However, this presents a significant challenge: between 2018 and 2022, 17,965 nonfatal lost-time injuries related to mining were reported by the National Institute for Occupational Safety and Health (NIOSH). Meanwhile, a collection of 123 international studies on mining incidents found that between 2010–2022, the rate of injuries in reported cases ranged from 4.4% to 10.6%.

What stands in the way of success for mining control room operators? Vast networks of monitoring technology and systems, new and old, that require 24/7 observation, quick decision-making, and real-time collaboration.

Integrated software solutions such as AV-over-IP and KVM video wall systems are emerging as the key to unlocking these capabilities in the mining industry and elsewhere. The goal is to provide mining operators in the control room with a centralized platform to manage and optimize all aspects of a mining operation.

What is a mining control room?

A mining control room refers to a station from which operators can manage multiple computers and systems related to a mining operation. It’s the command center or hub for an entire mining operation, providing a comprehensive view of activities above and below ground.

Mining operators in a control room need constant access to real-time data from various sources, including:

- Safety Systems: Gas detectors, proximity detection systems, worker wearables, and surveillance cameras.

- Production Monitoring: Equipment performance, material flow, and output tracking.

- Environmental Controls: Air quality, water quality, and ground stability monitoring.

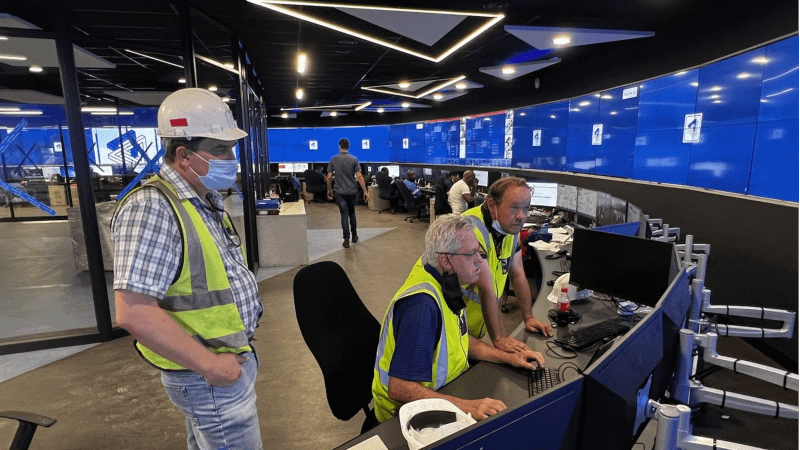

A mining control room run by Black Rock Mining Operations

What is a mining control room operator?

Within the mining industry, the term “mining operator” can refer to a wide range of roles depending on the specific type of machinery or equipment in use. In the context of this article, we’re talking about a mining control room operator rather than a machine operator. Control room operators monitor equipment, worker safety, production output, and critical environmental factor within a mining operation.

These skilled professionals are the eyes and ears of a modern mine, responsible for monitoring a vast network of systems and ensuring the smooth operation of the entire site. From tracking the location and safety of personnel to optimizing production output and minimizing environmental impact, control room operators play a crucial role in driving success in today’s mining industry.

Enhanced Safety in Mining Operations

Safety is paramount in the mining industry. The goal of any engineer or mining control room operator then is to eliminate hazards wherever possible and find safer alternative. Rigorous training, evolving safety protocols, and the continuous improvement of operational procedures are all critical factors to improve mine safety.

But within a mining control room, operators have even more tools at their disposal to keep an operation safe and running smoothly. Modern mining control rooms equipped with video wall technology further mitigate risks and protect workers via:

- Situational Awareness: Having real-time oversight of on-site activity from the location and well-being of miners to the performance of mining equipment and the status of environmental conditions.

- Real-Time Monitoring: These solutions enable rapid response in emergencies by integrating data from gas detectors, proximity detection systems (PDS), and worker wearables.

- Fast Communication: With a direct view of each department or team, mining control room operators have access to the entire operation simultaneously so if something goes wrong, they know exactly who to contact, where, and how.

Centralized Mining Operations

AV over IP systems enable mining control room operators to connect with a multitude of dashboards, information systems, optimization tools, HMI & SCADA to transform mining control rooms into dynamic nerve centers. With a centralized software management tool at their disposal, operators can control, configure and monitor all devices within the mining operation’s network from a single interface.

Integration with KVM and Videowall Systems

An integrated KVM (Keyboard, Video, and Mouse) and video wall system creates a powerful ecosystem for centralized control, real-time monitoring, and collaborative decision-making.

The combination of these technologies enhances operational efficiency, safety, and flexibility, making them essential in high-demand environments such as mining control rooms, industrial automation, and other mission-critical settings.

- Operators can manage multiple computers and systems from a single workstation without needing to physically move between terminals or workstations.

- All essential data and tools are accessible through one interface, saving time and reducing operational complexity.

- Operators can focus on their tasks rather than spending time navigating multiple devices or setups.

- Multi-view and windowing capabilities allow operators to monitor and control several systems simultaneously

- Operators can access and control systems remotely, reducing the need for physical presence in hazardous or remote areas.

Examples of integrated control rooms for mining operations

Here are just a few of the ways VuWall’s customers are using integrated KVM and video wall systems in their control rooms:

Integrated Operations Centre (IOC)

An IOC serves as the command center for managing mining operations. AV streams in these rooms transmit data from vital sources such as: production metrics, safety sensors, web applications, cameras and fleet management systems.

Benefits:

- Highly visible key performance indicators (KPIs) that update in real-time.

- Critical data can be quickly prioritized during emergencies through easily reconfigured displays.

Skills Development Centre

This type of control room setup ensures that training programs are interactive and driven by real-time data. The AV over IP system allows trainers to manage multimedia content, simulations, and live feeds.

Benefits:

- Real-time monitoring of practical exercises.

- Access to live operational data for hands-on learning experiences.

Condition Monitoring Room

Condition monitoring rooms focus on the health and performance of equipment and infrastructure. They aggregate sensor data and analytics for proactive maintenance.

Benefits:

- On-demand recall of important dashboards and information systems.

- Automated layouts to alert mining teams of critical events.

Conference Rooms

Boardrooms equipped with integrated AV systems benefit from centralized software management, ensuring smooth communication and collaboration between executives, engineers, and other stakeholders.

Benefits:

- Operational updates and presentations across locations.

- Unified platform for displaying live data, video conferencing, and reports.

- Access to all visual sources of the complete value chain in an executive environment.

Situation / War Room

During emergencies or critical decision-making scenarios, the situation/war room ensures that relevant data is immediately accessible.

Benefits:

- Instantaneous video wall reconfiguration to focus on critical data streams.

- Access to live production information, CCTV and other sources without impacting on the Operations in the Control Room.

The Future of Mining Control Rooms

The functionality and day-to-day management of mining control rooms has changed rapidly over the last several years. Between 1970 and 2010, NIOSH reported 26 mining disasters in the United States which resulted in 5 or more fatalities. Since 2010 there have been none. Although mining is still a dangerous industry with a high rate of reported individual incidents and numerous environmental challenges, technology is helping to curb the risks dramatically.

Centralized AV over IP systems with integrated KVM solutions, and advanced video wall technology help control room operators facilitate better data integration, communication, and minimize human intervention in dangerous areas of any mining operation. In addition to reducing risk of disaster or danger, an integrated mining control room simply makes the entire operation more efficient and cost-effective.

Improved Safety:

- Remote monitoring and control minimizes the need for operators to be present in hazardous environments.

- Real-time data visualization on video walls allows for faster detection of safety risks, while KVM integration provides immediate access to the systems needed to mitigate issues.

Operational Efficiency:

- A unified system allows operators and teams to visualize, analyze, and interact with critical data in real time, enabling informed and rapid decisions.

- Unified data visualization across the mining facility ensures that operators and decision-makers are aligned.

- Task prioritization is simplified, with critical alerts or data visually emphasized on the videowall.

Cost Savings:

- Proactive maintenance reduces equipment downtime and associated costs.

- Scalable solutions extend the lifecycle of AV systems.

- Centralized management lowers operational expenses and simplifies system updates and troubleshooting

To learn more about how VuWall’s integrated solutions, including advanced video wall technology, can help optimize your mining operation, contact us today.